Enlistment solidifying has turned into a crucial cycle in the assembling business. It guarantees metal parts are sturdy, impervious to wear, serious areas of strength for and. The presentation of enlistment solidifying scanners has altered how metal intensity therapy is performed. These machines give accuracy and effectiveness, assisting ventures with saving time and assets.

What is induction hardening?

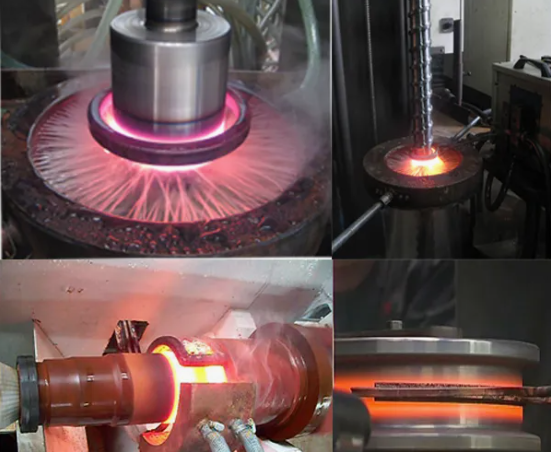

Induction hardening is an interaction where a metal surface is warmed utilizing enlistment warming. This is followed by fast cooling to solidify the metal. It works on the strength, wear resistance, and exhaustion life of metal parts. The innovation is generally utilized in the car, aviation, and tooling enterprises.

How Induction hardening Functions

Induction hardening Warming: The metal is presented to a substituting attractive field.

Heat Age: The metal warms up rapidly because of electromagnetic enlistment.

Extinguishing: The warmed metal is quickly cooled, frequently utilizing water or oil.

Significance of Enlistment Solidifying Scanners

Enlistment solidifying scanners mechanizes the interaction, giving more control and accuracy. They are exceptionally useful for enterprises requiring exact and repeatable outcomes. We should jump into the top advantages of involving induction hardening scanner for metal intensity therapy.

1. Accuracy and Control

Enlistment solidifying scanners offer exact commands over warming examples and temperatures. This results in uniform solidifying and guarantees that the main explicit region of the metal is impacted. The accuracy limits material contraction, further developing item quality.

2. Quicker Creation Times

Manual intensity therapy cycles can time-consume. Enlistment solidifying scanners altogether lessens this time. Via robotizing the cycle, makers can finish the solidifying system in a negligible portion of the time.

3. Energy Effectiveness

One of the top advantages of involving Induction hardening scanners for metal intensity therapy is energy productivity. Conventional intensity therapy strategies consume a lot of energy. Induction hardening scanners target explicit region of the metal, diminishing pointless warming and chopping down energy use.

4. Cost Investment funds

Energy productivity prompts cost reserve funds. Furthermore, quicker creation times and decreased squander likewise add to bring down functional expenses. Enterprises can see a huge profit from speculation by integrating these machines into their cycles.

5. Diminished Ecological Effect

Enlistment solidifying scanners produce less waste intensity contrasted with customary techniques. This adds to a lower carbon impression, making the interaction harmless to the ecosystem. Organizations hoping to embrace greener assembling techniques will view this as especially helpful.

6. Further developed Toughness of Parts

The top advantages of involving enlistment solidifying scanners for metal intensity therapy likewise incorporate the better toughness of treated parts. By solidifying just the surface while keeping up with the center's adaptability, the general strength of the part is improved. This is critical for ventures like auto and aviation, where sturdiness is fundamental.

7. Adaptability in Applications

Enlistment solidifying scanners can be utilized on various metal parts and shapes. This adaptability makes them appropriate for different ventures, from large equipment to more modest devices.

8. Reliable and Repeatable Outcomes

Conventional intensity therapy techniques can once in a while prompt conflicting outcomes. Enlistment solidifying scanners give steady and repeatable results, guaranteeing that each part meets the expected details without fail.

Utilizations of Enlistment Solidifying Scanners

The top advantages of involving induction hardening scanner for metal intensity therapy stretch out to different enterprises:

Car Industry: For driving rods, camshafts, gears, and other basic parts.

Airplane business: Guarantees high wear opposition for airplane parts.

Tooling Industry: Upgrades the strength of cutting and molding apparatuses.

FAQ’s

What is enlistment solidifying?

Enlistment solidifying is a metal intensity therapy process where the outer layer of a metal is warmed through electromagnetic acceptance and afterward quickly cooled. This upgrades the metal's hardness and toughness.

What ventures benefit from the acceptance of solidifying scanners?

Car, aviation, and tooling ventures now and again utilize these machines for exact and strong part solidifying.

What are the critical advantages of utilizing enlistment-solidifying scanners?

The top advantages of involving acceptance of solidifying scanners for metal intensity therapy incorporate accuracy, energy effectiveness, cost reserve funds, and quicker creation times.

Might all metals at any point go through Induction hardening?

Not all metals are reasonable for Induction hardening. It is fundamentally utilized for prepared and iron-based composites that can be heat treated.

Are there ecological advantages to utilizing Induction hardening scanners?

Indeed, they diminish squander intensity and energy utilization, making them more harmless to the ecosystem than conventional intensity therapy strategies.

How would I pick the right enlistment solidifying scanner?

Think about the kind of metal, part math, and creation volume while choosing a scanner.

Conclusion

The top advantages of involving enlistment solidifying scanners for metal intensity therapy make these machines a fundamental piece of current assembling. They give accuracy, energy proficiency, and cost reserve funds, while additionally working on the sturdiness of parts. Whether you're in the auto, aviation, or tooling industry, enlistment solidifying scanners offer a dependable and proficient answer for your intensity therapy needs. With their capacity to convey predictable and repeatable outcomes, these scanners are an important venture for any organization hoping to improve its creation interaction.

icons at the top right corner of the subsection.

icons at the top right corner of the subsection.